Approaches to Designing Wood Floor Trusses

Table of Contents

- Introduction

- Advancements in Design Software and Automation

- Integration of Sustainable Materials

- Prefabrication and Modular Construction

- Enhanced Connection Systems

- Smart Truss Systems

- Case Studies of Innovative Truss Designs

- Conclusion

Introduction

The construction industry is entering a new era in which technology and innovation converge to transform how load-bearing elements are conceptualized and built. Among these elements, wood floor trusses stand out for their adaptability, efficiency, and sustainability. Builders, architects, and engineers rely on these structural components to meet the evolving demands for strength, cost-effectiveness, and environmental stewardship in modern projects. Those looking for reliable wood floor trusses California can access an array of advanced solutions reflecting these technological leaps.

From residential homes to large commercial buildings, the importance of wood floor trusses has grown as design methodologies shift toward innovation and longevity. Recent years have witnessed a surge in the adoption of advanced materials, automation, and smart technology, each pushing the boundaries of what is possible in truss design. This article explores breakthroughs redefining wood floor trusses, offering insight for construction professionals and stakeholders seeking the latest in high-performance, sustainable building.

Advancements in Design Software and Automation

One of the most significant transformations in wood truss design stems from advancements in digital tools. Building Information Modeling (BIM) and Computer-Aided Design (CAD) platforms have empowered designers to create highly detailed, accurate truss configurations that minimize material usage while ensuring optimal performance. These tools enable digital simulations, enabling teams to test structural integrity and visual aesthetics before the first piece of lumber is cut.

Automation is another cornerstone reshaping manufacturing processes. With the integration of CNC machines, robotic saws, and automated assembly lines, the process from digital model to final product is seamless, efficient, and remarkably precise. This automation reduces the likelihood of human error and allows manufacturers to deliver standardized, high-quality trusses with shorter lead times. In large-scale projects where speed and consistency are paramount, automation streamlines workflows and slashes costs.

Integration of Sustainable Materials

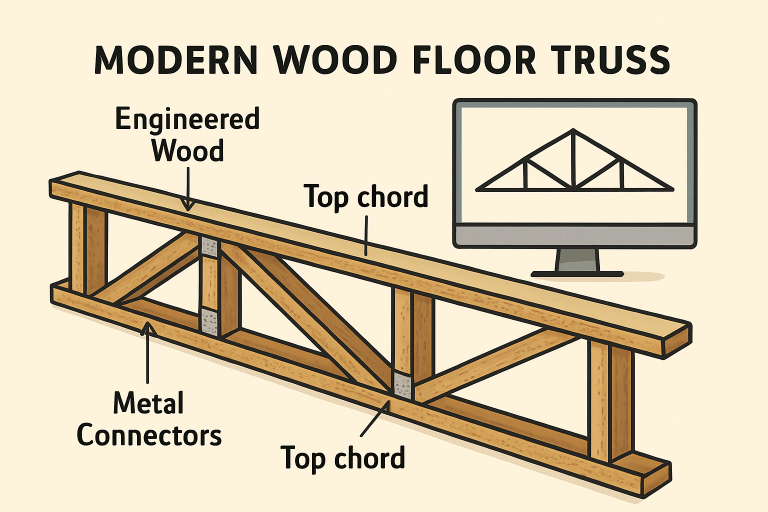

As sustainability moves to the forefront of construction, the materials chosen for truss fabrication are evolving. Engineered wood products like cross-laminated timber (CLT) and laminated veneer lumber (LVL) are being adopted because of their exceptional durability, uniform strength, and reduced environmental impact. Sourced from renewable forests and often manufactured from smaller, fast-growing trees, these engineered woods present a powerful alternative to traditional lumber, making them integral to green building practices.

Innovations are also being seen in the application of protective treatments. Fire-resistant coatings and advanced moisture barriers are standard in many high-performing trusses, extending lifespan and improving the safety profile of wood structures. The growing interest in low-emission adhesives and finishes reflects an increased awareness of indoor air quality and occupant health alongside environmental concerns.

Prefabrication and Modular Construction

Prefabrication has become a game-changer, increasing the efficiency and reliability of wood truss systems in new construction. By manufacturing trusses in a controlled environment, variables like weather are eliminated, and quality assurance can be meticulously maintained. Automated machinery guides each phase—from material cutting to plate pressing—resulting in incredibly precise, repeatable products that meet exacting standards. Prefabricated trusses are delivered directly to job sites ready for immediate installation, dramatically accelerating project timelines and minimizing costly on-site errors.

This streamlined approach benefits both safety and economics. Workers spend less time at dangerous heights, and the reduced need for correctional on-site labor translates directly into savings. Prefabrication and modular construction methods also pave the way for sustainable practices, providing opportunities to recycle offcuts and reduce overall waste.

Enhanced Connection Systems

Durable, straightforward connection systems are essential for ensuring long-term stability and safety in any truss design. A Chicago Tribune feature on open-web floor trusses highlights how modern connectors, high-performance fasteners, and specialized brackets help spread loads more efficiently while improving resistance to seismic activity, harsh weather, and daily wear. Manufacturers are also developing more intuitive connection options that streamline assembly, an essential benefit for large-scale builds or complex architectural configurations.

You can see this drive for easier installation and enhanced strength in the rise of custom plates, self-tapping fasteners, and multifunctional hardware that minimize the number of separate pieces needed without reducing structural reliability. Some of the latest systems are even designed to snap together, making them ideal for modular projects and rapid construction timelines.

Smart Truss Systems

Technological innovation has paved the way for the introduction of smart truss systems. Embedded sensors within trusses can actively monitor structural parameters, including load, humidity, temperature, and potential stress points. This real-time data collection enables facility managers and ownership teams to perform preventive maintenance, swiftly identifying problems before they escalate into system failures or safety hazards.

The most advanced smart truss solutions integrate with building management systems, allowing centralized oversight of building health and energy consumption. The added visibility and intelligence can not only extend the lifespan of the truss system but also contribute to overall energy efficiency and sustainable operation of the entire building.

Conclusion

The future of wood floor truss design is bright, marked by constant innovation, new material solutions, advanced connection strategies, and the ongoing integration of digital intelligence. As construction professionals continue to prioritize sustainability and efficiency, adoption of innovative approaches is set to accelerate, ushering in an era of safer, more intelligent, and more environmentally responsible buildings.