Comprehensive Guide to Industrial Lifts and Their Applications

Key Takeaways

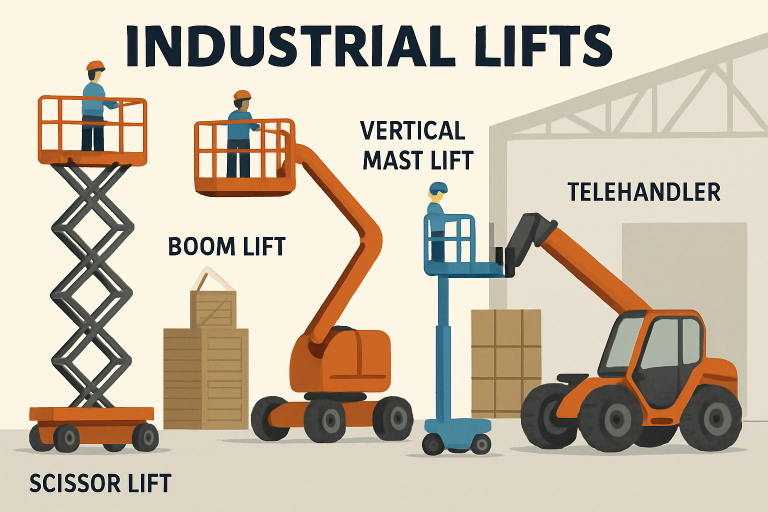

- Industrial lifts are integral to the safe and efficient movement of people and materials in various sectors.

- Each type of industrial lift has unique features and is suited for specific environments and tasks.

- Understanding capabilities, safety standards, and applications of lifts is crucial to selecting the right equipment.

Introduction

Industrial lifts are indispensable across construction, warehousing, manufacturing, and logistics. They provide solutions for safely elevating workers, goods, and equipment, optimizing productivity while minimizing manual handling injuries. Choosing the right industrial lift is essential to sustaining efficiency and promoting workplace safety. For a broad range of lift options and detailed product information, visit https://www.platformsandladders.com/lifts.

The right lift technology often determines how smoothly a site operates, whether you are maintaining high shelving in a warehouse or constructing multi-story buildings. Technological advances continuously expand the versatility of industrial lifts, catering to more specialized needs and improving compliance with regulatory standards.

Scissor Lifts

Scissor lifts provide stable, vertical elevation using a crisscrossed metal support structure. Their simplicity makes them ideal for jobs requiring frequent up-and-down motions, such as painting, wiring, or installing mechanical fixtures at medium heights. Electric models remain a favorite for indoor projects due to their quiet operation and zero emissions, while diesel-powered versions offer rugged performance for outdoor construction zones.

Commonly seen in warehouses, factories, and retail, scissor lifts can carry substantial loads, making them indispensable for maintenance and assembly tasks. Proper operator training and regular maintenance routines are vital for safe usage.

Boom Lifts

Boom lifts are designed for maximum flexibility in both reach and movement. Articulating boom lifts use jointed arms to maneuver around obstacles, ideal for accessing challenging locations such as roofs or behind fixed structures. Telescopic boom lifts (straight booms) extend far vertically and horizontally, making them a top pick for window cleaning, high-rise maintenance, and other applications requiring extensive reach.

Boom lifts offer a safer and more stable alternative to ladders or scaffolding for exterior building work. Their controls grant operators precise navigation around sensitive or complex work sites.

Vertical Mast Lifts

Vertical mast lifts are narrow and agile, designed specifically for indoor tasks in crowded or confined spaces. These lifts typically accommodate one person, making them perfect for jobs like changing overhead lights or retrieving items from high warehouse racks. Their slim profiles enable passage through standard doorways and operation in tight corridors.

Facilities management and retail stores often choose vertical mast lifts for quick, safe elevation where space restrictions would limit other equipment types.

Telehandlers

Telehandlers merge forklifts' and crane features, offering a versatile tool for lifting bulky items across variable terrain. The telescopic boom extends forward and upward, which allows operators to place loads on rooftops, scaffolding, or within large containers. Attachments such as buckets, grapples, or work platforms further boost a telehandler’s utility in agriculture, construction, and mining industries.

Operators must be mindful of load charts and terrain conditions, as improper use of telehandlers can impact stability, especially when the boom is fully extended. Their rugged construction and adaptability make them a staple in outdoor, large-scale operations.

Lift Tables

Lift tables use scissors to achieve smooth, adjustable lifting for goods and personnel. These platforms are invaluable at shipping docks, manufacturing lines, and anywhere ergonomic work positioning is critical. By enabling heavy loads to be safely raised or lowered, lift tables help reduce workplace injuries and enhance productivity through improved workflow organization.

Lift tables are also essential in automotive garages and assembly plants, where regular height adjustment supports precision work and operator safety.

Tail Lifts

Tail lifts are hydraulic or mechanical devices mounted on the rear of commercial vehicles. They streamline the loading and unloading process, eliminating the need for forklifts or manual lifting of heavy items. Tail lifts are vital to logistics, enabling safer, more efficient freight handling at distribution centers, warehouses, and delivery locations.

Using tail lifts significantly reduces the risk of musculoskeletal injuries among delivery drivers and warehouse staff who routinely handle bulky or awkward goods.

Vertical Reciprocating Conveyors (VRCs)

VRCs transport materials vertically across multiple floors in warehouses, distribution centers, and factories. Unlike passenger elevators, VRCs are specifically engineered for cargo, providing a reliable, heavy-duty option for moving pallets, containers, and products between elevations. Their robust construction and straightforward operation make VRCs invaluable where vertical movement is frequent and loads are substantial.

Safety interlocks and enclosure systems are standard on VRCs, preventing access during operation and ensuring compliance with stringent workplace standards.

Inclined Elevators

Inclined elevators operate on tracks at an angle, efficiently carrying loads or passengers up steep slopes where conventional lifts or elevators are impractical. These systems are used at construction sites, industrial plants, and hilly terrain for accessible transportation across significant elevation changes.

Inclined elevators deliver added convenience and enhance accessibility, especially in urban renewal projects or spaces with unique architectural constraints.

Final Thoughts

The diverse range of industrial lifts available today ensures that businesses and workers have the tools necessary to complete their tasks safely and efficiently. By understanding each lift type's unique features and optimal applications, organizations can improve productivity, reduce workplace injuries, and maintain compliance with safety standards. Investing in the right lifting solution is key to operational success across all industries.